Have you ever bought too much of something, or too little of something? Now take that context in business and get overstocked and understocked. When a business does not have control over their inventory, there is a likely scenario where they have too much inventory or too little inventory. But just how much does it negatively impact a business to be overstocked or understocked?

According to Spoiler Alert’s survey, 72% of businesses can only recover 50% or less of the cost of their overstocked inventory. Even further, only 4% can recover the cost of about 75%. For any business, that is incurring huge losses, all because they did not plan their inventory correctly.

In this article, I will explain what overstock and understock inventory mean and set boundaries for the overstock vs understock issues you might face. I will go over what causes these issues for a business and how much it affects the business’s operations. Additionally, I will go over how you can overcome these challenges and how you can best implement these strategies for your business to not have these problems in the future.

Definition Of Overstock And Understock Inventory

Both overstock and understock are inventory management failures in a business. However, they are the complete opposite of each other.

Overstock: Too Much Inventory

Overstock occurs when a company holds more inventory than it can sell or use in a reasonable amount of time. This excess inventory ties up capital and storage space, leading to increased carrying costs and potential wastage of resources.

Think of it as a business buying too much of a product because it was in hype. They tried to sell as much as possible. However, the demand for the product reduced as time went on. The remaining inventory is not sold, leading to an excess in inventory.

Understock: Not Enough Inventory

On the other side, understock is when a business does not meet the customers’ demands and stock fewer products than usual. This can result in lost sales opportunities, decreased customer satisfaction, and potential damage to the company’s reputation.

Understocking may arise from conservative inventory management practices. For example, a business does not believe in the hype of a new product and buys less of it. Within a few days, the business sells out all the products, but there are still customers looking to buy it. When you cannot meet the demand of the product, your inventory falls short.

Overstock Vs Understock Comparison

|

Overstock |

Understock |

| Excess inventory leading to increased costs | Insufficient inventory resulting in lost sales revenue |

| Inventory much higher than product demand | Higher customer demand than available inventory |

| Exceeds safety stock levels | Does not meet safety stock levels |

| Cause dead stock and increased storage spending | Customer dissatisfaction increases |

| Strains cash flow and profitability | Leads to lost customers and market opportunities |

10 Causes Of Overstocked And Understocked Inventory

Now that we have looked over the overstock vs understock inventory comparison, let’s now look at why these are caused. Even though they are opposite, their causes are the same! So here are the causes of overstocked and understocked inventory:

Cause#1 Inaccurate Demand Forecasting

Demand forecast looks at historical data to gauge what the future demand for your products will be like. Overstocked inventory usually arises because of inaccurate demand forecasting, where you might overestimate your customer’s demand and stock excess inventory ahead of time.

On the other hand, understocking occurs when businesses underestimate demand, resulting in insufficient inventory to meet customer needs. This can stem from overly conservative forecasting methods, lack of real-time demand visibility, or failure to anticipate sudden spikes in demand. For both inaccurate forecasts can lead to many problems with inventory. As a result, your business suffers.

Cause#2 Poor Inventory Management Practices

Since overstock and understock is an inventory management issue, poor inventory management practices are a major cause. For example, if a business handles inventory management manually, there is more likely to be human errors causing the problem.

Here, overstocking can occur due to inefficient inventory control practices, such as inaccurate inventory counts, inadequate stock rotation, or lack of inventory turnover analysis. Conversely, understocking can result from poor inventory replenishment strategies, such as irregular ordering patterns, excessive lead times, or insufficient safety stock levels. In both instances, poor practices affect your business negatively.

Cause#3 Supplier Issues

Sometimes, the issue is out of your hands. A supplier issue could cause your inventory to be overstocked or understocked. Overstocked inventory can result from supplier overdeliveries, where businesses receive more inventory than ordered due to errors in communication, inaccurate order fulfillment, or unexpected increases in production. This leads to excess inventory that exceeds storage capacity and ties up capital.

Similarly, understocking might be caused by disruptions in the supply chain. Suppliers might not deliver your inventory on time because of strikes or blockades which are out of your hands. This leads to supplier shortages or delays in fulfillment, resulting in stockouts and missed sales opportunities.

Cause#4 Seasonal Fluctuations

Seasonal fluctuations is the place where demand forecast inaccuracies are seen the highest. Failure to adjust inventory levels to accommodate seasonal fluctuations in demand can lead to both overstocked and understocked inventory.

Overstocking may occur when businesses maintain high inventory levels during off-peak seasons, resulting in excess inventory that becomes obsolete or requires clearance sales.

Understocking can happen when businesses fail to anticipate increased demand during peak seasons, leading to stockouts and disappointed customers. Both result in missed opportunities during what could have been a profitable time for your business.

Cause#5 Failed Promotional Marketing Strategies

To deal with seasonal fluctuations, businesses often conduct promotional strategies. For example, holiday marketing is seen as a way to gather interest in your product. However, if that fails, then you can run into such inventory problems.

Promotional overbuying is a common cause of overstocked inventory, where you might buy excess inventory to take advantage of bulk discounts or promotional offers without considering actual demand. This can result in surplus stock that remains unsold after the promotion ends, leading to inventory write-offs or clearance sales.

Understocking may occur due to over-promotion. Your marketing campaign was so good that it had the opposite effect of what you were looking for. This results in stockouts and lost sales opportunities. Customers will quickly look for alternatives and result in great losses for you. It might also affect your brand perception as not reliable enough and over-promising in marketing.

Cause#6 Inefficient Product Life Cycle Management

For inventory, they have a life cycle where they are most likely to be sold or be rendered useless in your warehouses. Overstocking often occurs when businesses neglect to phase out obsolete products or slow-moving inventory, leading to excess inventory that occupies valuable storage space and ties up capital.

Understocking may result from failure to introduce new products or replenish popular items in a timely manner, leading to stockouts and missed sales opportunities. Again, this is most likely caused by inaccuracies in data or supply chain disruptions. Thus, inefficient management of the product lifecycle can contribute to both overstocked and understocked inventory.

Cause#7 Economic Uncertainties

Other than supply chain disruptions, there are economic uncertainties that can cause your inventory mismanagement. Factors such as market downturns or uncertainties can disrupt demand forecasts and contribute to both overstocked and understocked inventory.

Overstocking may occur during economic downturns when you anticipate decreased demand, so you stock up in advance. This excess inventory build-up might be a precautionary measure. But, all the dead stock is holding up the capital, and you are unable to move it. And understocking may result from sudden increases in demand during economic upturns, where you don’t have enough inventory to meet your customer’s demands.

Cause#8 Insufficient Funds

Another limitation is lack of funds. You might think lack of funds can only lead to understocking, but overstocking can occur as well. Understandably, you might not have the financial resources to source inventory, causing understocked inventory and increased customer dissatisfaction.

Overstocking may occur if you tie up all the money in product procurement and not invest it in demand forecasting for inventory management solutions. This type of disproportionate spending might lead to your business buying more inventory than you can handle. This further increases your costs, which you might cut in the future. Then, you don’t have enough capital to buy products in the future. It is a never-ending cycle and your brand’s reputation takes a tremendous hit because of failure to satisfy your customers.

Cause#9 Industry Related Challenges

Each industry is different and needs unique insight into inventory management or else they might suffer. For example, the food industry is a great example. Perishable goods mean the life cycle of the product is quite short and complicates inventory management.

As such, overstocking may occur if businesses fail to effectively manage inventory turnover rates or anticipate changes in market demand, resulting in excess inventory that becomes obsolete. Similarly, understocking may result from a crop failure, which limits inventory for businesses. So each industry requires experts who can anticipate problems with inventory before they occur to avoid stockouts or overstocking.

Cause#10 Lack of Data-Driven Decision Making

Failure to utilize data-driven decision-making processes can make overstocked and understocked inventory situations worse. Overstocking may occur when businesses rely on gut instinct or outdated forecasting methods rather than focus on data analytics to predict demand and optimize inventory levels.

Understocking may result from insufficient data analysis or reliance on static inventory models that fail to account for changing demand or the introduction of new product alternatives. Not all businesses can handle data collection or even analyze the data correctly. This will cause both overstocking and understocking issues.

Results And Consequences Of Overstock Vs Understock Inventory

So what happens because of overstocking and understocking? Let’s have a look:

Results Of Overstocked Inventory

- Increased carrying costs, including storage expenses and potential markdowns

- Risk of inventory obsolescence and spoilage

- Difficulty in selling outdated or slow-moving products

- Negative impact on cash flow and inventory control

- Decreased warehouse efficiency and productivity

- Potential damage to brand reputation because of outdated or excessive inventory

All these result in a need to overhaul your business’s current inventory management. It is not a simple matter either. Implementing a new system will take time to get used to. While that is happening, handling all the overstocked inventory significantly reduces your cash flow.

Possibly the worst is the hit your brand perception might take because of this. Customer reviews are a permanent mark and an increased negative review might force future customers to look for their products elsewhere because yours are currently outdated and you cannot stock new products because of your reduced capital.

Consequences Of Understocking Inventory

- Missed sales opportunities and lost revenue

- Dissatisfied customers due to stockouts and delayed order fulfillment

- Negative impact on customer loyalty and brand reputation

- Increased risk of competitors capturing market share

- Potential damage to relationships with suppliers or distribution partners

- Decreased efficiency and productivity

Understocking causes customer dissatisfaction, more so than overstocking. The consequences of understocking are immediately felt and that resonates with customers. They will be dissatisfied with your business and look elsewhere. So understocking not only damages your business, but it increases business for your competitor in the process.

Such damage to your business is both impactful immediately and affects you in the long run. You might also ruin the trust between you and your suppliers. So in this, understocking might be the worse of the two because it affects your business immediately and there is little time to solve those issues.

Effective Inventory Management: 8 Ways To Deal With Overstock And Understock Inventory

So how do you deal with understocked or overstocked inventory? The answer is effective inventory management. Here are some ways that you can use to help deal with inventory problems like this:

Way#1 Demand Forecasting Optimization

Knowing what your future demand will be like can help your business avoid overstocking or understocking inventory. For this, you need to use historical data can help you understand when you should be stocking up on important inventory. Along with that, future trends is a key metric to watch out for. Regular review and adjustments to your demand forecasting can help you optimize your inventory.

Way#2 Regular Inventory Audits

Knowing what your current inventory state will also help you avoid inventory management issues. Here, regular inventory audits allow you to identify and eliminate excess or obsolete inventory. By optimizing inventory levels to match actual demand, your business can reduce carrying costs and minimize the risk of overstock situations. It will also help you identify which inventory strategy you should be using to best tackle any inventory issues you might encounter.

Way#3 Agile Supply Chain Management

Inventory is king for businesses and you want to make sure you have enough inventory to keep your customers satisfied. So instead of tying your inventory down to one supplier, you could try multiple sourcing strategies instead. Through strategic vendor relationships, you can solidify your inventory procurement. You could also place real-time inventory visibility for your suppliers to make inventory management a collaborative effort to help reduce stockout and dead stock risks. By adopting an agile supply chain management like this, your business will have sufficient inventory, eliminating the need to worry about overstocked or understocked inventory.

Way#4 Just-in-Time (JIT) Inventory Practices

Just-in-time inventory is when you procure your inventory when you need them from suppliers. For example, you are running low on a certain product. When it reaches below the safety stock, you can then order the product. Implementing this helps you minimize excess inventory and reduce carrying costs because you get the inventory when you need them. It’s difficult because miscommunication between you and your suppliers will increase lead times. That is why you need to establish close relationships with your suppliers to help optimize your safety stock levels.

Way#5 ABC Analysis For The Right Inventory Purchase

ABC analysis is one of the best inventory management practices because it puts your inventory into perspective on how well they perform. Category A is your fast selling inventory, while category C is your slow-moving products. With ABC analysis, you can streamline your inventory procurement process so you don’t overstock or understock on inventory. When you separate your inventory into tiers, it makes inventory management easier because you know which products to target for procurement and which ones you don’t need.

Way#6 Dynamic Pricing Strategies

While the rest is on the inventory management side, don’t forget customers buying your product is also necessary for your business. Not only is it about earning a revenue, but it also guarantees that your products are always in motion and not being hindered by holding costs. For this, having dynamic pricing allows you to change prices on the fly so you improve your sales. One way to handle dynamic pricing is by offering product bundles where you group products together to increase chances of selling them. You can also implement pricing tiers for your bundles to cover a larger customer base.

Way#7 Technology Integration

Technology is great because it minimizes how much work you have to do while increasing your efficiency. For overstock and understock inventory issues, an inventory management software will help you make both managing and optimizing inventory much easier. Automation tools can allow you to reorder inventory when they are low on stock. It helps reduce human error and leaves you with more time to come up with strategies to tackle the issue at hand.

Way#8 Continuous Improvement and Learning

Nothing is perfect and there are bound to be times when you have to deal with overstocking or understocking your inventory. That is why there is a need to learn from your mistakes and continuously improve. For instance, holding yearly training sessions helps your company adopt the most effective methods for your employees. You could also attend your industry-related seminars and conferences to learn more about upcoming trends that might help your business. Learning is a continuous process and will allow your business to improve in the future.

Using A Bulk Order App To Deal With Overstock And Understock Inventory On Shopify

Inventory management in e-commerce is just as important. For example, an online shop on Shopify has third party apps that can assist with inventory management. There are also apps that can help implement inventory management strategies to help with overstocked and understocked inventory.

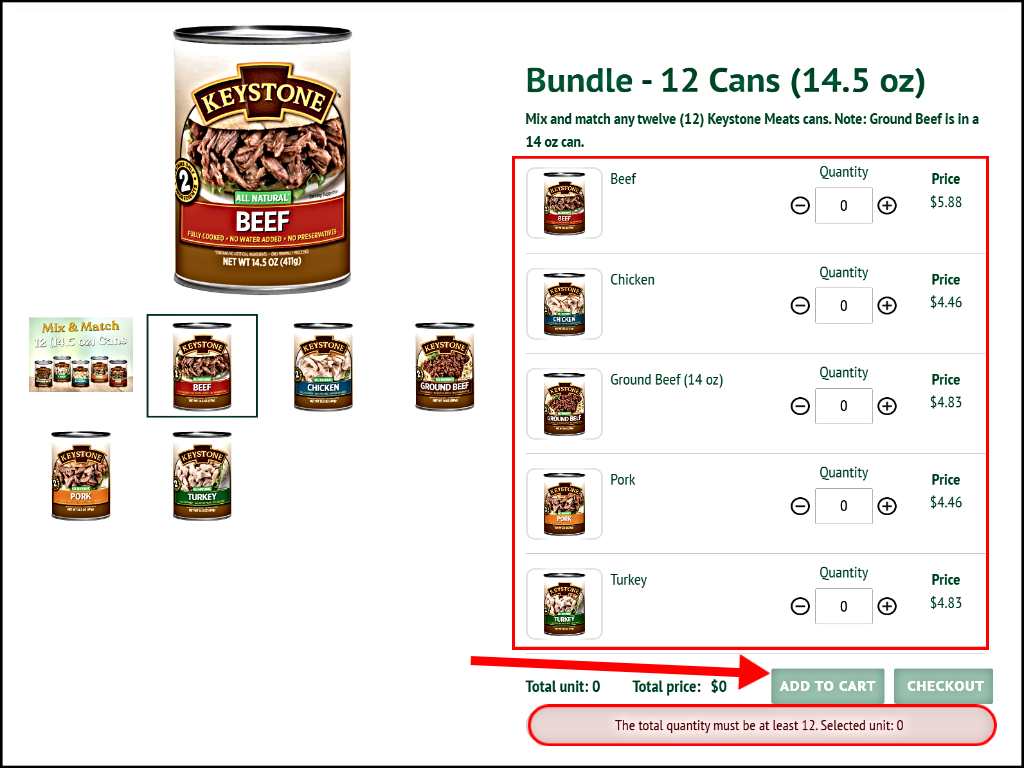

Here is an example of a bulk order app with a mix-and-match product bundle feature on Shopify:

MultiVariants Bulk Order App With Mix And Match Product Bundle Feature

You can see that the different variants of the product are all shown on one store page. Customers can choose how many they want in their bundle of 12, which helps personalize their shopping experience. However, until they fulfill the rule restriction at the bottom, customers are not allowed to add the bundle to cart. But when customers chooses the correct quantity, they are allowed to add the bundle to cart, and all their variants will be added in one click.

So how does this help with overstocked and understocked inventory? A mix-and-match bundle like this helps to combine slow-selling variants with faster selling variants. It combines them and gives them more chances of being sold, helping your business reduce dead stock.

Also, it helps increase the average order value as customers have to buy 12 products at once for this bundle. The restriction here ensures that the customers cannot buy the bundle without fulfilling the requirement. It gets rid of mistakes when ordering a bundle. And the one click add-to-cart button simplifies the shopping process for your customers.

So you help reduce non-essential inventory, create product bundles for your shop, increase order value of transaction, and a more streamlined shopping experience for your customers. All these solutions in one app can help manage inventory better while also increasing sales at the same time.

Bottom Line

Overstock vs understock: both create much problems for your business. The causes are all down to poor inventory management that leads to too much inventory or too little that your customers are unsatisfied. With the right ways and strategies, you can help eliminate these problems from your store and have increased sales without the additional costs!