For B2B businesses, there are specific processes that every business should follow. Probably the most important one out of them all is managing inventory. You can say that inventory is the lifeblood of all B2B businesses.

According to Deloitte, 6% of poor-performing supply chains that conduct inventory management can grow in revenue. That is significantly low, which highlights why inventory management is so crucial for the growth of a B2B business.

In this article, I will highlight the importance of inventory management in a B2B business is for your B2B business and how you can follow the best practices to maintain optimal business performance. I will also showcase how you can implement a simple MOQ strategy on Shopify to manage your B2B inventory.

Understanding B2B Inventory Management – Definition And Types

Before we dive into the importance of inventory management in B2B business, we first need to have a basic understanding of what inventory management is.

Inventory comprises all the goods and materials a business possesses, whether the finished products are ready for sale or the raw materials and components used in production. At each stage of inventory being used, the inventory has to be accounted for in the business.

Therefore, B2B inventory management covers the entire inventory lifecycle within a B2B business, from acquisition to utilization and sale. It involves keeping track of inventory levels and optimizing the flow of goods throughout the supply chain.

Types of Inventory Management Systems

There exist many different types of management systems that help manage B2B inventory. Here is a brief look at them:

- On-Premise Software: This refers to inventory management systems installed and operated on the business’s premises. They require in-house infrastructure and maintenance.

- Cloud-Based Software: These systems are hosted on remote servers and accessed via the Internet. They offer flexibility, scalability, and accessibility from anywhere with an internet connection.

- Open-Source Software: Open-source inventory management systems provide source code access, allowing users to modify and customize the software according to their needs without vendor lock-in.

- Point-of-Sale (POS) Software: POS systems manage inventory in real-time at the point of sale. They track sales, inventory levels, and transactions, streamlining the checkout process and inventory updates.

- Barcode Scanning Software: This software uses barcode scanning technology to accurately track inventory levels and movements. It improves efficiency by reducing manual data entry errors and streamlining inventory management processes.

- Virtual Inventory Management Software: Virtual inventory management involves managing inventory that may not physically exist in the warehouse. It includes dropshipping, cross-docking, and just-in-time inventory methods, optimizing supply chain efficiency and reducing storage costs.

5 Key Factors Highlighting The Importance Of Inventory Management In A B2B Business

Now that we understand inventory management, it is time to highlight the key factors that make it essential in a B2B business.

Factor #1 Demand Forecasting

With proper inventory management, a B2B business can make calculated business decisions regarding its inventory and how to utilize it best. That is where demand forecasting makes up a big part of inventory management in a B2B business.

By predicting future product demand, businesses can adjust their inventory levels accordingly, ensuring they have the right amount of stock available when needed. This approach helps prevent overstocking or understocking situations, optimizing inventory management processes.

Factor #2 Inventory Tracking

Alongside demand forecasting. Consistent tracking of inventory is another critical component of inventory management. It is where inventory is tracked at every stage of the production and selling process.

By closely monitoring stock levels, movements, and changes in inventory status, B2B businesses can maintain real-time visibility into their inventory. This allows your business to promptly identify and address any issues, such as slow-moving or dead stock, discrepancies in inventory counts, or delays in the supply chain. Ultimately, consistent tracking enables businesses to make informed decisions and respond effectively to changes in demand or supply.

Factor #3 Product Categorization

Prioritization is essential for effective inventory management in B2B businesses. Your inventory can be messy if you don’t have proper inventory and product categorization. That is where inventory management helps make your inventory make sense, making it easier to manage and make quick business decisions.

Businesses can allocate resources efficiently and focus on managing critical items by categorizing inventory items based on their importance, demand, or profitability. This ensures that resources such as storage space, capital, and manpower are allocated appropriately to meet customer demand and maximize profitability. Product categorization strategies, such as ABC analysis, help businesses optimize their inventory management efforts and improve overall operational efficiency.

Factor #4 Automation

B2B businesses have to deal with extensive inventories regularly. There are ways that inventory management can make managing these extensive inventories more efficient and streamlined. One way is automating inventory management.

Businesses can automate routine tasks such as inventory tracking, replenishment, and order processing. A great example of this is reorder-point automation. A reorder point is when you are running low on inventory. When that happens, the automated inventory management will immediately contact suppliers to reorder more of the same products.

Automated inventory management systems reduce manual errors, improve accuracy, and increase efficiency by eliminating the need for manual data entry and paperwork. It can also help improve your business’s B2B inventory and order tracking. Additionally, integration with other business systems enables seamless data exchange and process automation across different departments, enhancing overall operational efficiency and productivity.

Factor #5 Collaboration

B2B inventory is nothing without being able to cooperate and coordinate with other businesses. That is where collaboration is a key factor in making inventory management important in a B2B business.

Collaboration is crucial for optimizing inventory management in B2B businesses. Your business can ensure smooth supply chain operations by building collaborative, solid efforts through proper communication channels with suppliers and distributors.

Close collaboration with suppliers facilitates timely delivery of raw materials and components, reduces lead times, and minimizes supply chain disruptions. Sharing inventory data and forecasts with key partners enables better coordination, allowing suppliers to effectively plan production schedules and inventory levels to meet demand fluctuations.

Collaborative inventory management practices promote closer integration between supply chain partners, improving inventory visibility, reducing inventory holding costs, and enhancing overall supply chain performance.

7 Practices To Maintain Effective B2B Inventory Management

Now that we understand the factors that make inventory management so important, it is time to ensure that your business maintains an optimal level of inventory management. Here are the practices that you need to consider to remain on top of your inventory management game:

- Centralize Inventory Data

- Monitor and Analyze Inventory Data

- Invest in Virtual Inventory Management System

- Conduct Staff Training

- Regularly Review and Update Inventory Policies

- Build Stronger Relationships with Vendors and Suppliers

Practice #1 Centralize Inventory Data

Many B2B businesses have multiple locations where their inventory is kept. This can create a logistic problem when trying to keep track of inventory. That means spending more time and money to keep inventory in check. Inventory management like this will cause a negative cash flow in inventory control.

One way to solve this is by centralizing your inventory data, where all the inventory data and stock are kept in one location. This streamlines inventory tracking, reduces the risk of discrepancies or errors, and enables better coordination and decision-making across the organization. Along with that, collaboration efforts are made much more accessible.

Practice #2 Monitor and Analyze Inventory Data

Data is critical to understanding your business’s growth. For data-driven B2B sales optimization, you must analyze and constantly monitor your inventory. You must monitor key performance indicators (KPIs) such as inventory turnover, fill rates, and stockouts.

With proper inventory data monitoring and analysis, you gain valuable insights into customer demand. Also, you get to understand how your supplier performs, so you know whether you need to make changes. Proper analysis allows you to leverage your inventory management to improve operational efficiency and profitability.

Practice #3 Invest in Virtual Inventory Management System

While on the topic of having inventory in multiple locations, another helpful practice is integrating a virtual inventory management system into your inventory management. These systems provide real-time visibility into inventory levels, locations, and movements, allowing businesses to manage inventory more effectively across their supply chain.

Not only will this help make inventory management more manageable, but it will also show where you can make your inventory operations more efficient. This is especially helpful for B2B customer segmentation strategies for your B2B business.

Practice #4 Conduct Staff Training

Nothing beats a well-trained staff. Even with all the latest technology, your staff utilizes it for inventory management. Training should cover areas such as using inventory management software, understanding inventory policies and procedures, and handling inventory-related tasks such as receiving, storing, and picking stock.

Investing in staff training improves accuracy and efficiency in inventory management operations. Training staff regularly ensures that your staff is up-to-date with industry practices and new knowledge to implement in inventory control. So, ensure that your business keeps up-to-date with the latest trends in inventory management.

Practice #5 Regularly Review and Update Inventory Policies

If training is a must-have practice in your business, then reviewing your inventory policies is just as important. The B2B market is often limited to a small customer base. It is fast-moving and cut-throat. If your business is not maintaining the industry standard in inventory management, then your business is sure to fall behind against competitors.

So that B2B inventory management policies and procedures are regularly reviewed and updated. This could be quarterly or yearly, but it has to be done. With this practice in your B2B business, you can evaluate key areas to improve your inventory management.

Practice #6 Openly Communicate With Your Vendors

Last but not least, you need to maintain a good relationship with your vendors and suppliers. They are the ones who are providing your business with the necessary inventory to do business. Creating strong vendor relationships is essential for your B2B business success.

It would help if you went about it by being open with your data and communicating with your vendors and suppliers. If they have trouble fulfilling your order, you get to know them beforehand. It will help strengthen your relationship with them. The key to B2B business is fostering a long-term relationship with your vendors. That way, you can grow your business alongside them.

By building stronger relationships with vendors and suppliers, your B2B business can enhance communication, trust, and cooperation, improving inventory management practices and overall supply chain performance.

Implement MOQ Strategies With A Bulk Order App On Shopify

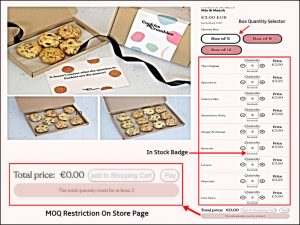

So, we learned about inventory management and the best practices to ensure your inventory is properly controlled. But it can be overwhelming once your business has started and your inventory is over the place. There are many strategies that you can implement for your store. Here is an example of a Shopify store using a mix-and-match bundle app to enforce minimum order restrictions on their store to maintain inventory levels:

This store sells cookies while letting customers choose which variants they want in the mix-and-match box. On top of that, the customers can choose boxes of 5, 8, and 12 cookies. Then, the app displays all the variants with an in-stock badge to show customers the available variants.

You will see that the add to cart button is not highlighted at the bottom of the product page. The store owner has applied an MOQ restriction to the app. This ensures that customers are precisely the amount that will fit in the box.

An MOQ restriction like this helps prevent overselling or underselling the product. It allows the store to manage its inventory and have proper control. Additionally, the variant display allows the customer to choose the variants they want all in one product page instead of multiple product pages. It streamlines the customer’s shopping experience, encouraging customers to confirm their purchase and reducing cart abandonment.

Bottom Line

Inventory management is essential in a B2B business. There are some practices that all B2B businesses should follow so that they can optimize their inventory management. Overall, whatever inventory management strategies your company uses, inventory should be the number one priority for all B2B businesses.