For any B2B business, revenue is essential. It dictates whether a company will be able to expand operations or not. One of the most important for companies is ensuring the inventory is well-stocked and ready for customers. A B2B business with properly managed inventory is crucial for that success.

This is because the US Census Bureau recently released data on how businesses hold $1.36 of inventory for every $1 sale. That is a small margin of error that a B2B business has to face, and there are so many inventory risks involved that only one problem can shut down a business.

So, here, I will be discussing inventory risks. I will help you understand the risks involved with inventory. Also, I will discuss how identifying and addressing inventory risks in B2B can help your business improve inventory management with key solution tactics.

What Is Inventory Management In B2B? – Definition and Importance

First, let’s define inventory management.

Inventory management is a simple concept. It tracks goods in your inventory, whether in a warehouse or your brick-and-mortar shop. Inventory management also tracks the movement of your products up and down the supply chain. So, we can say that inventory management tracks B2B inventory and order tracking all across the supply chains. That whole process is what inventory management deals with for a B2B business.

So, inventory management deals with a lot more than inventory itself. From the buying to the eventual sale, everything between that concerns inventory management. There are many significant risks in inventory management because of how important it is. That is why inventory and risk management are essential for a B2B business.

6 Major Inventory Risks For B2B Businesses

There are risks involved with any business. B2B businesses run into inventory risks, so let’s look at some of the significant risks for your B2B business in inventory management.

Risk #1 – Inaccurate Demand Forecasting

Demand forecasting is essential for a B2B business. It helps keep track of the demand for your products. In addition, it tells you how much product you need on hand to maintain smooth operation. However, inaccurate demand forecasting can be a significant inventory risk.

If your B2B business has inaccurate forecasting, you have too much or too little stock. This increases the cost of holding inventory when too much is in stock. It also reduces cash flow when you have too little inventory on hand.

Risk #2 – Unreliable Vendor And Supplier

Suppliers and vendor relationships are the lifeline for a B2B business. They are providing the raw materials and goods that you sell for revenue. A good vendor or supplier ensures these products get to your business on time and reduces lead times with proper inventory management. However, if you can’t rely on your vendors, keeping an appropriate inventory for your customers will be challenging. It leads to looking for new vendors, and now you are up to 5 different vendors.

One unreliable vendor can be sorted, but having many suppliers creates inventory risks. This is especially true when vendors and suppliers are prone to cybersecurity vulnerabilities. One cybersecurity issue can compromise your entire business operation. That is why unreliable suppliers can become a significant inventory risk.

Risk #3 – Limited Inventory Shelf Life

The problem with some products is that they have a short or limited shelf life. Some products can last for years on end. However, you have perishable products on the shelf that do not last more than a week. If the goods spoil, you have no revenue for that product.

Limited inventory shelf life can hinder a B2B business inventory. If your business cannot sell the products in time, you will lose revenue. Then you have to get rid of the expired products from your warehouse. As you get rid of the products, it creates a mess for your inventory management. This is why limited inventory shelf life can eventually become an inventory risk.

Risk #4 – Inventory Shrinkage Through Mismanagement

Inventory shrinkage is a significant concern for B2B and one of the most extensive inventory risks. It is the inventory loss due to theft, product damage, and mismanagement. Forbes reported that inventory shrinkage was responsible for $46.8 billion in 2018. This has only increased since then.

It is the mismanagement that a B2B business needs to worry about. Improper tracking of inventory leads to problems in management. Inventory mismanagement might be the reason for inventory shrinkage from theft and damage to inventory.

Risk #5 – High Costs In Inventory Management

The cost of handling inventory is often overlooked. There are risks where you overspend in inventory management when you should focus on other parts of the business, like branding.

The primary reason for high costs in inventory management is small costs add up together to become high costs to your inventory. While it might not seem much initially, the cost becomes a huge burden for your business. Costs such as overhead, handling, and storage costs are just a few to consider for inventory management.

When costs increase, your customers are ultimately the ones who have to pay the expenses. The cash flow in inventory management is what causes this to happen. Prices of goods rise and lead to decreased sales over time. This is not just an inventory risk but also a business risk that needs to be considered. Otherwise, it has the potential to ruin your entire business operations eventually.

Risk #6 – Bullwhip Effect On Supply Chain

Sometimes, a small change leads to a significant change somewhere else. That is what the bullwhip effect on the supply chain is referring to. This effect refers to the slight change in demand leading to changes in the supply chain. It comes on suddenly and without much warning. B2B businesses feel the worst effects, especially in inventory management.

For example, your business and your competitors are all buying up excess inventory to deal with the increased demand for your product. Suppliers and vendors are overwhelmed, causing inventory management disruption across all supply chain channels. This leads to future disruptions where there is a shortage of inventory. Disruptions lead to shortages, leading to the suffering of your B2B business in the long run. All of this is from a tiny change in the supply chain.

6 Key Solutions For Inventory Risks

We explored the inventory risks that a B2B business can face. So, now it is time to move on to their solutions. Here are the 6 key solutions when identifying and addressing inventory risks in B2B:

Solution #1 Proper Demand Forecasting With ABC Analysis

Product analysis is essential for inventory management when selling to other businesses. One way that you can do this analysis is through ABC product analysis.

You can set this category by seeing how fast your inventory moves for the product. Or you can see which product has the highest value. With proper product analysis, your business can make more accessible demand forecasts.

This will help keep inventory in check. You can make sure you are not overstocking on the wrong products. Proper demand forecasting will help your inventory management and reduce inventory risks. Risks like inventory shelf life become less of a concern when you know how fast you can move them. Thus, ABC product analysis minimizes the risk of inaccurate demand forecasts and helps with data-driven B2B sales optimization.

Solution #2 Transparency And Collaboration With Vendors And Suppliers

There is no denying that working with vendors and suppliers is a big problem. However, vendor relationships are integral to inventory management success. You must be transparent and collaborative with your vendors and suppliers.

Transparency means sharing information and reviewing each other’s performance. You can measure how well your vendors are doing by checking how many of your orders with them are on time. These key performance indicators (KPIs) are helpful in understanding where you can improve inventory management.

This will not only help with inventory management but also deepen the relationship. A collaborative effort on both parts is important. When both businesses understand how each other works, it will help reduce inventory risks.

You can also assess your vendors’ risks and help them improve. You can help your vendors and suppliers assess security risks. Such collaboration will only help your B2B business in the future. As a result, your suppliers will help you in the future and be more welcoming of changes.

Solution #3 Regular Inventory Audits

Zippia’s statistics on inventory management show surprising details. 43% of small businesses do not track their inventory, and 21% report not having an inventory. If an SME cannot track its inventory, it can spell disaster for managing it.

So, how do you know how your inventory is doing? Performing regular inventory audits helps reduce inventory risk, such as inventory shrinkage. An inventory audit will look at your financials and match them with the inventory you have in hand. An audit like this makes sure you have the correct amount of products. There are no discrepancies in your inventory, and you can manage your inventory better.

It does not have to be an audit every day. Regular inventory audits will help you understand if you are overstocking or understocking. It also detects inventory loss and helps improve your inventory management.

You can do inventory audits by physical count followed by inventory count reconciliation. You can also include cycle counting to keep track of a select few items of inventory you want to keep a closer eye on. Some businesses prefer software so they can keep track of inventory in real time.

Whatever way your business may conduct inventory audits, it is essential to do so. Knowing how much inventory you have, your business can reduce inventory risk. Inventory management becomes streamlined and a lot easier to conduct with these audits.

Solution #4 Cost Reduction Methods In Inventory Management

I have already mentioned how high inventory management costs are a business risk. So, how should a company reduce costs to handle inventory management better? Here is a list of cost-reduction methods that you can take for your inventory management:

-

- Just-in-time inventory (JIT) can be a unique way to get your order of products while also reducing costs for carrying or handling inventory. JIT means that you order products when they are needed so you are not overburdening the company’s assets trying to hold inventory.

- Setting reorder points for inventory is an excellent way to manage inventory. You can set reorder points when your inventory starts to get low. You can set up the reorder points by analyzing when reorders for a product are needed. It reduces uncertainty with reordering and ensures you don’t end up with excess inventory that increases costs.

- Dropshipping is another suitable method that doesn’t require handling excess inventory. You let a third party manage your inventory. This reduces inventory costs by allowing the third party to deal with it.

- Bundling products together can also be a great way to reduce the inventory you must check. You can bundle complimentary products together. This can help move the slow-moving products when paired with a fast-moving product. That way, you are not left with handling dead stocks and reduce the cost of inventory management.

These methods can help reduce the cost of inventory management, reduce inventory risks, and ensure your business is running smoothly.

Solution #5 Centralizing Purchase Of Key Inventory

We saw how the bullwhip effect on the supply chain affects inventory management. A solution for that is to centralize the purchasing of key inventory. You can do this by having a team dedicated to buying supplies for your business.

The team can deal with product analysis and demand forecasting. If there are shifts and changes in the supply chain, your team will have full visibility. They can see when a bullwhip effect is likely to take place and act accordingly.

With a centralized team to do this, your inventory management is streamlined and not disrupted by market changes. Additionally, centralized purchasing will also reduce the chances of inventory shrinkage over time.

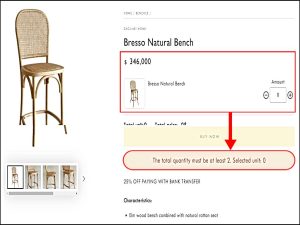

Solution #6 MOQ With Third-Party Bulk Order App

Third-party applications can reduce inventory risks with minimum order quantity restrictions. There are many inventory management systems available for Shopify stores. If you are a B2B business that sells products in bulk, take this Shopify store using a bulk order app with a MOQ restriction for example:

In this bulk order app, you can see a minimum order quantity that needs to be fulfilled before adding it to the cart. A MOQ like this can help keep your inventory in check. In addition, MOQs will also ensure that you balance holding costs and handling costs and reduce inventory risks even further.

With the right demand forecasting, you can confirm the right MOQ for your products. The right MOQ helps so that you are not overselling with a low MOQ or underselling with a high MOQ. A one-click bulk order app on Shopify like this makes it possible to implement MOQ strategies, so your inventory is always in check.

Not only that, but third-party software like this can streamline the shopping experience for your customers as well. You can move the products in high demand and stock appropriately with the MOQ restriction in place for your online store. It is the best of both worlds and keeps your inventory in check with more efficiency.

Bottom Line

As a B2B business, you want to ensure your customers get their products. With the proper inventory management, this is possible. However, there are many risks involved in it. That is why identifying and addressing inventory risks in B2B is vital to a business’s success. Once you have identified the risks with the right solution, your B2B business will succeed.