B2B Inventory Management is not only about counting boxes. It is about keeping things moving. The process must be fast, smooth, and accurate, even when juggling hundreds of product variations. Take gloves as an example. Suppose it has ten sizes and six colors with sixty SKUs. One wrong move and you are either oversold or buried in slow stock.

That is how most B2B sellers lose money.

When items are out of stock, people walk away. This happens more than you think. And it is expensive. 69% of shoppers abandon purchases due to stockouts, causing $1 trillion in annual missed sales globally (BIGCOMMERCE).

If you do not want to lose your customers, then you are in the right place. In today’s article, we tell you everything you need to know about managing B2B inventory efficiently. All the best strategies await you. Let’s go!

- Effective B2B inventory management requires real-time tracking and automation to avoid stockouts and overstocking.

- Automated systems save time and ensure accurate inventory updates across multiple variants.

- Forecasting and AI can help predict demand and optimize orders based on past data.

- Efficient warehouse setup, such as storing high-demand items up front, minimizes picking time.

- Regularly clear out dead stock to maximize space and maintain profitability.

Table of Contents

Why B2B Inventory Management Needs More Than a Spreadsheet

Variants Turn Simple Into Chaos

Suppose a product has five sizes and four colors. That is already 20 variants in total. Now do the math across your entire catalog. Without a solid b2b inventory management system, you overstock what does not move and run out of what does.

Example: A furniture wholesaler orders equal quantities of 5 sofa colors in 3 sizes. After launch, 70% of customers choose gray in large. The others barely move. Now they are overstocked in beige and short on what sells.

You need to know what is selling and act fast when it does. That is the heart of multi-variant B2B inventory management.

B2B Is Not Retail

A retail customer grabs two mugs. A B2B buyer wants 200 with scheduled deliveries and tiered pricing.

You cannot treat those the same.

Example: A coffee shop chain places an order for 1,000 branded mugs, split across five locations, delivered monthly over six months. That is very different from someone buying two mugs on your online store.

If you treat it like B2C, you will ship late, show the wrong stock, and lose repeat business. That is why inventory control for B2B needs a different approach.

Strategies That Keep You In Control

Let us now learn how to make b2b inventory management easier and more efficient. Learn these strategies by heart and watch your sales skyrocket.

1. Track Stock Live, Not Later

If you do not see inventory in real-time, you are flying blind.

Let’s say large blue hoodies spike in demand. If your system shows low stock immediately, you reorder. If not, you oversell. Then you are explaining delays and issuing refunds.

Example: A sports apparel wholesaler sells out of size L training pants after a team places a last-minute order. With real-time B2B inventory management updates, they caught the low inventory, reordered immediately, and avoided disappointing the next client.

Live data means fast decisions. Fast decisions keep customers.

2. Automate or Fall Behind

Manual tracking? It is slow. It breaks. And eventually, so will your ops.

Set rules. If the stock drops below 20, the system creates a PO. Done.

Example: A medical supply distributor automates alerts and POs for surgical masks. When any variant drops below the threshold, reorders are triggered instantly, avoiding costly downtime.

Now you are not stuck in spreadsheets. You are scaling. That is the power of automated B2B inventory management tracking systems.

3. Fix Your Warehouse Flow

Bulk orders slow you down if your space is not set up right.

Start simple. Put bestsellers close. Barcodes on everything. Clear labels. Fast pick zones.

Example: An electronics wholesaler uses ABC analysis to keep top-selling chargers near the front. Lesser-ordered cables go farther back. Pick time drops by 30%.

Less time looking means more orders shipped. That is a solid B2B inventory management strategy for warehouses.

Tools Making B2B Inventory Management Easier

Shopify’s Got the Bones for B2B

Shopify is not just for retail. It is built to handle B2B, too, if you use it right.

Selling cleaning supplies in packs of 100? Set minimum order rules. Need to update 50 SKUs at once? Use bulk editing.

Example: A janitorial supplier uses Shopify to manage multi-SKU inventory for B2B, updating pricing and stock across hundreds of variants with one click.

You can run lean even with a giant catalog. That is B2B stock management software done right.

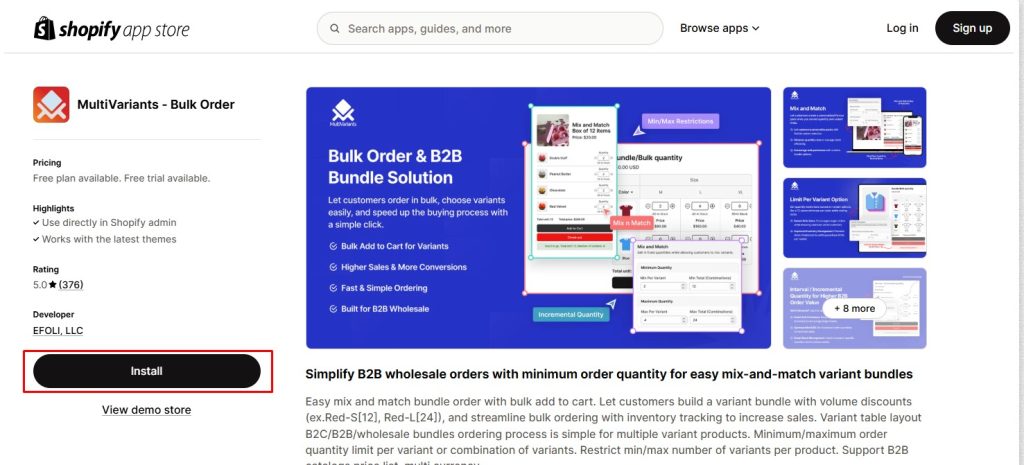

Some superb variant inventory management apps can help you manage large orders. Below is a simple guide to using one of these apps to manage bulk orders with multiple product variants.

- Install the App

First, go to the Shopify app store from the admin dashboard and install the app.

- Add Your Products and Options

Once installed, add your products and set up the available options (e.g., size, color, material).

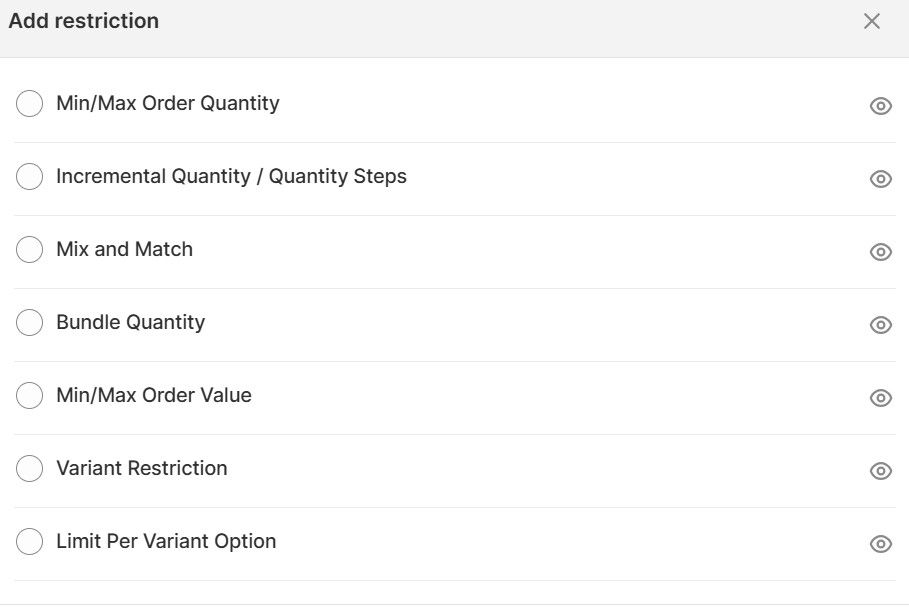

- Configure Complex Variant Restrictions

Configuring complex variant restrictions will give you stronger control over your inventory. Choose any one of these options according to your needs.

Check out the tutorial that explains all the options in detail.

- Save the Settings and Test Your Configuration

Save the settings and test your configurations, ensuring your customers can only select valid combinations. You can go back and change the settings within a few seconds.

The app reduces both manual work and manual errors. Your b2b inventory management has become a lot easier thanks to this automation app.

All the product combinations and their stock status will appear on the product page. Out-of-stock badges will appear automatically if you run out of items, as shown below. Hence, resulting in fewer errors and more efficiency.

Forecasting = No Guesswork

Look back. Learn. Plan better.

Last December, XL thermal jackets vanished. This year, you ordered more ahead of time. No scrambling. No missed sales.

Example: A holiday décor wholesaler uses B2B inventory forecasting based on two years of data. They increased orders of snowflake lights by 40% and sold out with zero leftovers.

Forecasting helps you prep instead of react. It is key to scaling B2B inventory for growth.

Cut the Waste. Keep the Cash.

Stop Hoarding Dead Stock

If something has not moved in 6 months, stop ordering it.

Run a discount. Clear it out. Use the space for what sells.

Example: A kitchenware wholesaler had 300 green spatulas collecting dust. They bundled them in a “starter set” promo. Gone in a week.

This is how you stay profitable without playing inventory Tetris.

Get Real With Your Suppliers

Want better deals? Be a better buyer.

Order more regularly. Ask for lower rates. Lock in restocks before the rush hits.

Example: A B2B pet food brand negotiated 10% on every order by committing to a monthly volume. When demand jumped during pet season, their supplier gave them top priority.

Better terms give you breathing room and keep your shelves full when demand spikes. That is real B2B inventory management optimization.

What Is Coming Next

AI Is Already In the Game

AI spots trends. It notices slow-moving items. It adjusts future orders without you touching a thing.

Example: A beverage supplier noticed that the lemon flavor was slowing down. AI flagged it and reduced the next order automatically before they noticed the dip.

Less guesswork. More accuracy. That is the future of B2B Inventory Management. You will be left behind if you do not act fast and start implementing AI into your operations.

Ship Smarter, Not More

Do not send 10 boxes when one will do.

Group shipments. Cut packaging. Spend less. Waste less.

Example: A supplier switched to weekly consolidated shipments instead of daily shipments. They saved $2,000 in freight and reduced packaging waste by 40%.

It’s good for the planet. Even better for your bottom line. That’s a smart B2B warehouse management strategy in action.

Bottom Line

B2B inventory management is what will drive more sales and get more customers. If you are still tracking manually, you are behind. You need a system that updates itself, spots problems early, and helps you stay one step ahead.

Inventory is not just stock. It is the heartbeat of your business. Keep it clean. Keep it fast. And if you are on Shopify, install an inventory management app that can make it all easier. We are rooting for you. And do not forget to share this article with others who may need it.

FAQs

What makes B2B inventory tough?

Big orders, custom schedules, and too many variants to count.

How do I manage all these SKUs?

Track everyone. Automate updates. Do not do it by hand. That is what you call multi-variant inventory management.

Why go real-time?

Because slow updates = lost sales. Real-time data is the backbone of reliable inventory control for B2B.

How does automation help?

It does the boring stuff so you can focus on growing. That is where automated B2B inventory track systems shine.

Best warehouse setup?

Keep the most in-demand items close. Label everything. Keep it tight. That is a smart B2B warehouse management strategy.

Does forecasting help?

Absolutely. Past sales tell you what’s coming. That is smart B2B inventory forecasting.

What software features matter most?

Minimum orders, SKU tracking, bulk edits, Shopify-ready tools, all signs of good B2B stock management software.

How to ditch dead stock?

Spot what is not selling. Stop reordering it. Run promos. That is solid B2B inventory optimization.

Want better supplier deals?

Order in bulk. Stay consistent. Ask for better terms.

Trends to watch?

AI-powered forecasting. Sustainable shipping. Both are critical for scaling B2B inventory for growth.