Are you struggling to keep your inventory under control? Most of the business face this problem initially. That’s where efficient inventory management term comes in. Managing inventory efficiently in B2B wholesale forms the backbone of any successful business.

There are various strategies to streamline inventory management, including enabling B2B preorders to check demand, managing backorders with transparency, automating inventory tracking, and offering discount tiers for overstocked products.

Studies show that businesses with optimized inventory management can reduce carrying costs by up to 30%. Additionally, real-time inventory tracking can improve order accuracy by 25%, boosting customer trust and loyalty.

In today’s fast-paced business era, smart inventory practices can give your business a significant edge – helping you prevent stockouts, minimize overstocking, and maintain a seamless supply chain. In this article, we will learn about the different types of inventory management systems and top 10 tips to manage inventory.

- Efficient inventory management reduces carrying costs, prevents stockouts, and boosts customer satisfaction.

- Key tips include using preorders, automating inventory tracking, and forecasting demand for better planning.

- Minimum order quantities (MOQ) and seasonal planning help optimize stock levels and prevent overstocking.

- Leveraging third-party apps like MultiVariants automates tasks and simplifies managing complex variants.

- Building strong supplier relationships and maintaining real-time inventory sync across channels improves efficiency and reduces errors.

Table of Contents

Types of B2B Inventory Management Systems: Choose the Right One for Your Shopify Store!

As like all business types are not the same, that’s like all the inventory management systems are not the same. There are five main types of inventory management systems available in b2b Shopify.

Type#01: Virtual Inventory Management

In the B2B sector all kind of businesses needs to manage their inventory. Managing inventory effectively ensures that the right products are always available to meet customer demand while avoiding stock shortages or excess inventory.

With the proper inventory management tools, businesses can track stock levels, automate restocking, and maintain better control over their supply chain.

Shopify offers built-in inventory management features and integrations with third-party apps. That makes it easier for B2B businesses to streamline processes and keep their inventory in check.

Type#02: B2B Order Management System

B2B order management software helps to make ordering easier for B2B companies. Businesses may benefit from more effective order and stock management.

There are many B2B order management software available like the MultiVariants-Bulk order app. These features are designed to help B2B merchants manage their inventory and regularly update their data.

Type#03: Barcode Inventory Management System

The method uses barcodes to track inventory levels, making it easier to control stock levels and automate restocking procedures.

A barcode inventory management system is a tool that helps businesses track and manage their stock using barcodes. Each product is assigned a unique barcode, making it easier to scan to quickly update stock levels, track sales, and monitor inventory movement. This inventory management system reduces human errors, saves time, and improves accuracy in stock management.

For businesses using Shopify, barcode inventory management becomes even easier. Shopify supports barcode scanning through apps and tools that integrate with its platform.

Type#04: Periodic Inventory Management System

A Periodic Inventory Management System helps track their stock by counting inventory at specific intervals, such as weekly, monthly, or annually, rather than updating stock levels in real-time.

Unlike a Perpetual Inventory System, which continuously records inventory changes, the periodic system relies on physical stock counts to define inventory levels and calculate the cost of goods sold.

This system is commonly used by small businesses or those with simpler inventory needs because it is cost-effective and requires minimal technology.

Type#05: Perpetual Inventory Management System

This system offers real-time inventory tracking, allowing businesses to monitor stock levels and reorder products as needed.

With a perpetual inventory system, every item is recorded at each stage of its movement within the business. It ensures you always have the latest data on your inventory. Most inventory management software relies on this system to keep track of products efficiently.

Top 10 Tips for Managing Inventory Efficiently in B2B Wholesale

There are many types of inventory management available, but the solution might differ from business to business. What’s best for you might not be the best for others.

Here, you will get a proper idea of what type of inventory management system you need to optimize your business.

Moreover, streamlining inventory management isn’t just about reducing costs – it’s about implementing a system that supports your growth and keeps your customers happy.

We’ve explained 10 strategies/tips, from preorders and automation to seasonal planning and supplier relationships. If you implement these ideas, you can master your B2B wholesale order efficiently.

- Enable B2B Preorders to Check the Demand

- Manage Back Orders with Clear Visibility

- Automate Inventory Tracking and Notifications

- Ensure Seamless Inventory Sync Across All Channels

- Use Data-Driven Insights to Forecast Demand and Reorder

- Implement Minimum Order Quantities (MOQ) for Efficiency

- Optimize Warehouse Layout for Better Organization

- Plan for Seasonal Inventory Needs

- Offer Discount Tiers for Overstocked Products

- Strengthen Relationships with Wholesale Suppliers

Tip#01: Enable B2B Preorders to Check the Demand

B2B preorders allow businesses to estimate demand before stocking up on products. By enabling preorders, you create anticipation among buyers while gaining insights into how much stock you need.

Why it’s valuable:

- It helps prevent overproduction and stocking less than you need.

- Helps to ensure a steady cash flow before even investing in the inventory.

Takeaway: Use preorders as a forecasting tool to plan your inventory and avoid unnecessary storage costs.

Tip#02: Manage Back Orders with Clear Visibility

Backorders help retain sales even when stock is low, but unclear communication can lead to customer dissatisfaction. Transparency in backorder management is key to maintaining trust.

Best Practices:

- Display which products are available for backorder and estimated restock dates.

- Send automated updates to customers regarding order status.

Takeaway: Prioritize restocking back-ordered items first to ensure customer satisfaction and repeat business.

Tip#03: Automate Inventory Tracking and Notifications

Manual inventory tracking is time-consuming and prone to errors. Automating this process helps maintain accurate stock levels and ensures smooth operations.

Why automation matters:

- It saves time and reduces human errors.

- Prevents stockouts by triggering timely reorder alerts.

Takeaway: Integrate inventory management software to track stock levels in real time and optimize your supply chain.

Tip#04: Ensure Seamless Inventory Sync Across All Channels

For businesses selling on multiple platforms, maintaining synchronized inventory is crucial. A centralized system ensures accurate stock updates across all channels, preventing overselling.

How to achieve this:

- Automate the updating of inventory across all platforms.

- Monitor stock movement and distribute inventory strategically.

Takeaway: Choose a system that offers real-time inventory syncing to avoid errors and improve customer experience.

Tip#05: Use Data-Driven Insights to Forecast Demand and Reorder

Analyzing past sales trends helps businesses predict demand and maintain the proper stock levels.

Why it works:

- Ensures popular items are always available.

- Ensures that there are no unnecessary overstocking or cash flow issues.

Takeaway: Review sales reports, seasonal patterns, and supplier lead times regularly to improve forecasting accuracy.

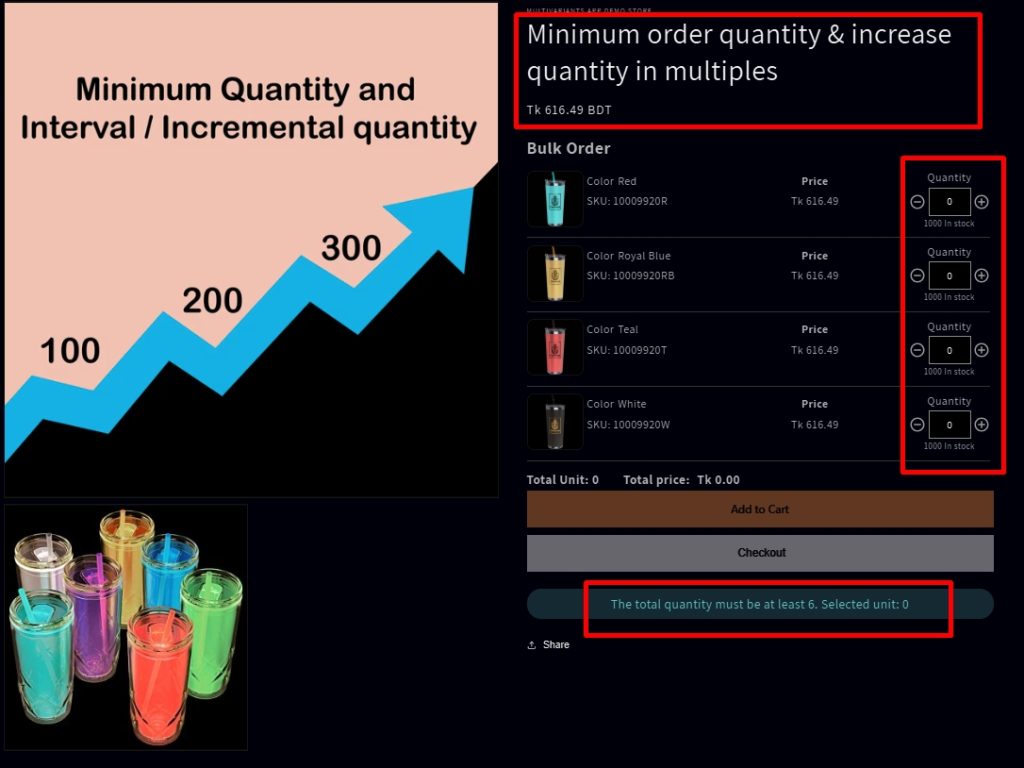

Tip#06: Implement Minimum Order Quantities (MOQ) for Efficiency

Setting up custom quantity increments or MOQ helps prevent small, unprofitable orders from depleting stock and ensures efficient inventory usage.

Why it’s important:

- Minimum order quantity encourages more profitable orders.

- Helps maintain stock for high-value clients.

Takeaway: Communicate MOQ policies to your buyers upfront to manage expectations.

Here’s a detailed video tutorial on how to set up custom minimum and maximum quantity increment ranges using a Shopify app.

Tip#07: Optimize Warehouse Layout for Better Organization

A well-organized warehouse speeds up order fulfillment and reduces errors. An organized warehouse encourages salesmen to maintain orders and helps them to keep track of it.

Best practices:

- Store high-demand products in easily accessible locations.

- Use barcoding and labeling for accurate stock tracking.

Takeaway: Conduct regular warehouse audits to optimize storage space and improve efficiency.

Tip#08: Plan for Seasonal Inventory Needs

Seasonal trends can impact inventory requirements, making advanced planning crucial. Regularly checking social media sites and staying up-to-date on what’s trending can help you stock the right items and boost seasonal sales.

Why it matters:

- This method prevents stock shortages during peak seasons.

- Also, helps to reduce overstocking of seasonal items in off-peak months.

Takeaway: Use historical sales data to predict seasonal demands and check new trends to adjust inventory accordingly.

Tip#09: Offer Discount Tiers for Overstocked Products

When stock levels are high, offering quantity discounts using the best Shopify automatic discount app can help move products quickly while maintaining profitability.

Why it’s effective:

- Clears out slow-moving inventory.

- Encourages bulk purchases, improving cash flow.

Takeaway: Bundle slow-moving items with high-demand products to increase sales.

Here’s another one for setting up bundle quantity increment dropdown for bulk orders using the Shopify bulk order app.

Tip#10: Strengthen Relationships with Wholesale Suppliers

Reliable suppliers ensure a steady stock flow and adaptability to market changes.

How to build strong partnerships:

- Maintain open communication about demand forecasts.

- Work with flexible suppliers to accommodate changing order volumes.

Takeaway: Diversify your supplier network to mitigate risks and avoid supply chain disruptions.

Wrapping Up

We know managing inventory efficiently is important for maintaining a smooth business operation, reducing costs, and ensuring customer satisfaction.

Since every business has unique needs, there isn’t a one-size-fits-all solution. The key is to find the right inventory strategy that aligns with your business model, sales patterns, and operational goals.

Sometimes, it feels overwhelming, but you’re not the only one who faces this. The good news is that modern inventory management software can automate tracking, prevent stock issues, and streamline your entire process.

With the right tools, signifying demand accurately, and staying proactive, you can turn inventory management from a challenge into a strategic advantage for your business.

Better inventory management means better efficiency, happier customers, and increased profitability.

FAQs

What Do You Understand about ABC Inventory Analysis?

ABC analysis is a method in which inventory is divided into three categories, A, B, and C in descending value. The items in the A category have the highest value, B category items are of lower value than A, and C category items have the lowest value. It is crucial to control and manage inventory in a business.

What is EOQ in Inventory Management?

Economic order quantity (EOQ) is the ideal quantity of units a company should purchase to meet demand while minimizing inventory costs including, holding costs, shortage costs, and order costs.

How Can a Retailer Manage Its Inventory Efficiently?

By using automated tracking systems, retailers can manage inventory efficiently. Moreover, synchronizing stock across all sales channels, forecasting demand with data insights, setting minimum order quantities (MOQ), and organizing their warehouses effectively. Regular stock audits, transparent backorder management, and seasonal inventory planning also help optimize inventory control.

What are the Five Costs of Carrying Inventory?

Carrying costs include the cost of renting the warehouse where businesses keep their stock, operating the warehouse, paying the salaries of the employees working at the warehouse, any loss of inventory due to theft and damage, and ensuring the safety of inventory.

What is The Lead Time in Inventory?

For inventory management purposes, lead time indicates the time it takes to complete a purchase order. For example, if it takes 5 days from the date of ordering a shipment to then reach the selected spot in your warehouse, the lead time for shipment is 5 days.