Overstocking can be a bigger issue for a wholesaling business. Carrying costs are still incurred when surplus inventory is left unsold. According to Spoiler Alert’s research, carrying expenses account for 20-30% of total inventory costs. That’s a big slice of the pie that you can start shrinking by setting a proper minimum order quantity.

So, we gathered all the information you need! In this article, you’ll learn about minimum order quantity. We hope you’ll also understand its importance for your business and how it will impact your profit. We’re also going to give some tips for optimizing MOQ for B2B businesses.

Table of Contents

How Minimum Order Quantity Affects a Wholesale Business

MOQ is very important for any business. We’ll explain this with an example.

Suppose I make plain T-shirts. A customized shop wants to buy 10 t-shirts from me. I have to pay for the raw materials and labor. It will cost me at least $300. I can’t charge $30 for one T-shirt, can I? Even if I do, I won’t see any profit.

Let’s create another scenario. The shop orders a larger amount of T-shirts – say 50 T-shirts. I can purchase raw materials in bulk at a much cheaper price. This lowers my production costs to just $200. By selling 50 t-shirts at just $6 apiece, the supplier still nets $300. This will be enough to cover production costs and secure some profit for their effort.

What is Minimum Order Quantity

A supplier or manufacturer usually sets the minimum order quantity (MOQ) for maximum wholesale success. It specifies the least amount of a given product that a provider is ready to offer.

Let’s talk about a store selling T-shirts. It says that you can’t buy just one T-shirt. Instead, you have to buy 3 pieces together. That’s what a MOQ is

It might seem counterintuitive at first setting a limit. However, manufacturers have other costs, such as raw materials and labor costs. Setting a limit makes it more profitable for them. They can ensure they don’t lose money in the production process in this way.

Also, it depends on the demand for the item. A vendor might consider imposing a minimum limit on a product if there is significant demand for it.

Types of MOQ

You can divide MOQ into two different bases.

Type #1 Who is setting the limit

There are two types of minimum order limits.

- Supplier Set: Suppliers set the limits themselves. The brands have to maintain the limit while purchasing from them. They set the MOQs just to ensure they don’t lose money on a production run.

- Brand Set: Brands can also institute MOQs for end customers. However, this isn’t a common case.

Type#2 How many limits are there

Just like the previous one, we can divide MOQ into two types.

- Simple MOQ: As the name implies, simple MOQs are SIMPLE. You settle on a single minimal amount. An excellent example would be a customized goods seller. If a buyer was only planning to buy one mug or pen, it wouldn’t be worth the resources required to add a logo or color scheme. It takes a lot of resources to add a logo or color scheme. So, if a buyer only buys one mug or pen, it wouldn’t be worth the resources for the seller.

- Complex MOQ: Purchasing from a provider who has a complicated minimum order quantity (MOQ) will entail meeting two or more conditions. Both a minimum order value and a minimum quantity of units may need to be met. The requirements can be considerably more complicated.

Impact of MOQ On Inventory

MOQ will significantly impact your inventory management. Suppose you set a high MOQ. You might face capital entanglement, overstocking, and increased storage costs. However, if the MOQ is too low, customers will order more. But it will cost you a higher shipping charge and administrative costs.

Impact of High Minimum Order Quantity

Positive:

- Minimized admin, order processing, and inventory costs

- Reduced risk of stock-outs

Negative:

- High investment of working capital

- High holding costs

- Increased risk of product obsolescence

Impact of Low Minimum Order Quantity

Positive:

- Reduced holding costs due to a lower level of inventory

- Lower investment of working capital

- Reduced risk of obsolescence

Negative:

- Frequent review and ordering of products

- Higher admin, order processing, and inventory costs

- More exposure to demand and supply issues

- Greater risk of stockouts

4 Steps to Set Minimum Order Limits for Wholesale Businesses

It’s important to be purposeful with the minimum order quantity setting process. It takes more than simply announcing the new change. You can’t set the MOQ without considering market conditions. You have to calculate the target MOQ and inform existing customers. Here is how you can do everything properly.

- Consider Market Condition

- Calculate the target MOQ

- Inform existing customers

- Set the MOQ with a Bulk-Order App

Step#1 Consider Market Condition

You have to understand how the market is going. Analyze factors such as customer behavior, industry trends, and competitor strategies. It will allow you to identify opportunities and capitalize on them.

Step#2 Carefully estimate the target MOQ

Initiate by calculating the appropriate MOQ for each product. We will discuss this in more detail in the next section.

Step#3 Inform existing customers

Let your existing customers know well in advance. Inform them even if they normally meet the MOQ. Try to find ways to continue working with buyers who don’t meet the MOQ. You might lose some customers in this process.

Step#4 Set the MOQ with a Bulk-Order App

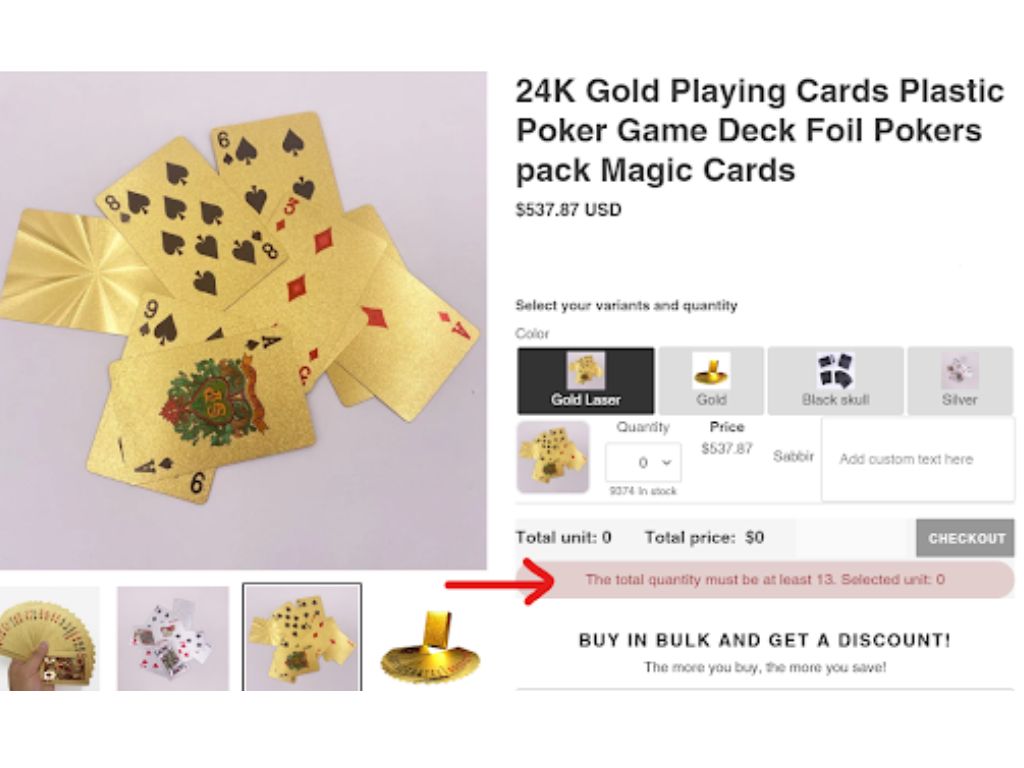

The easiest and simplest way to set minimum order quantities for a Shopify Store is to use the bulk order app. It’s a simple and easy-to-use app. This app offers lots of options and functionality.

With such an app, you can control the limits on your products by variant, by option, and by order value. Check out the free version before fully committing to it.

Calculate The Best Minimum Order Limit For Your Wholesale Business With 4 Steps

Calculating the Minimum Order Quantity (MOQ) will ensure both economic viability and efficiency. We organized a step-by-step guide just for you!

- Determine Demand

- Calculate Your Break-Even Point

- Understand Your Holding Costs

- Come Up with Your MOQ

Step#1 Determine Demand

Analyze historical sales data, industry trends, and consumer preferences. You can project future demand for your product with this information. Make predictions about how many things you will sell in a specific time frame. You can use statistical techniques of forecasting software. Think about any upcoming trends or seasonal variances that could impact demand.

Step#2 Calculate Your Break-Even Point

Determine all of the fixed expenses—such as rent, salary, and equipment costs. Calculate the unit’s variable costs including labor, materials, and other expenses. These might change depending on the volume of production. Use the formula to calculate the number of units you need to sell to cover all your costs:

Break−Even Point=Fixed Costs/(Unit Selling Price−Variable Costs per Unit)

Step#3 Understand Your Holding Costs

Calculate the total cost of inventory storage including account taxes, insurance, and warehousing costs. Think about the potential cost of having money that could be used elsewhere locked up in inventories. To determine the overall cost of maintaining inventory, add together these expenses.

Step#4 Come Up with Your MOQ

While keeping your MOQ low enough to attract customers and accurately reflect demand, it should be large enough to cover your break-even point and lower holding costs. Consider the MOQs your suppliers have established and how they affect your inventory if you’re a store. Examine typical MOQs for related items and in your sector. To get the best balance, you might need to experiment with various MOQs. Be ready to modify in response to comments and sales information.

Significant Changes You’ll See on Your Sale If You Use MOQ

Any B2B business wants to ensure their company’s sustainability and efficiency. Implementing minimum order quantities can be the first step to achieving it.

- Covering production costs and ensuring profitability

- Streamlining the production process

- Enhancing quality control and speed

- Maintaining business viability

- Creating mutually beneficial relationships

- Increasing profit margin

Changes #1 It will cover your production costs and ensure profitability

One of the main reasons for implementing MOQ is to cover fixed production costs like labor, materials, and machinery setup, maintaining their profitability.

Changes #2 It will streamline the production process

Suppliers maximize manufacturing efficiency, cut waste, and improve resource management by producing more in greater, steady volumes.

Changes #3 It’ll enhance your business’s quality control and speed

Better quality control and faster turnaround times are made possible by higher, steady production volumes, which guarantee a steady supply of goods for consumers.

Changes #4 MOQ will maintain your business viability

By ensuring that each order improves the supplier’s bottom line, MOQs help to sustain the supplier’s business model.

Changes #5 It’ll create mutually beneficial relationships

MOQ maintains the consistency of production processes, quality, and lead times. It helps wholesalers like you build better relationships with factories and business owners.

Changes #6 It will increase your margin profit

MOQs for suppliers are typically configured to guarantee a specific profit margin. They frequently wait to place new stock orders until their sales are high enough to generate an operational profit. This implies that the safety net customers require will be provided even at a relatively modest MOQ.

Tips For Optimizing Minimum Order Quantities For B2B Business

Imagine this scenario as a customer. You need a face wash but your favorite brand says the minimum quantity is 2. Many customers may not buy the product. So how can you make them?

No matter what type you do – wholesaling business or retailing – here are some tips to make MOQ more effective.

- Create incentives for a higher spend

- Free shipping thresholds for customers

- Eliminate slow-moving SKUs

Tip#1 Create incentives for a higher spend

You can require MOQs for bulk buyers to help ensure retailers pay you a minimum amount. In exchange for a minimum spend, you may choose to offer order volume discounts. You will charge the retailer less per unit in exchange for a higher guaranteed overall spend. Adjust the prices to help incentivize higher spend.

Tip#2 Free Shipping thresholds for customers

Free shipping thresholds can lead to increased conversions. Ship the orders to customers after they spend a certain amount. You can also offer free shipping for first-time customers. It will increase the conversion rate.

Tip#3 Eliminate slow-moving SKUs

Get rid of any less popular products that customers aren’t willing to purchase in bulk quantities. This will enable you to make significant financial savings.

Bottom Line

Set a smart minimum order quantity for maximum wholesale success. It signifies fewer small orders, higher revenue, and smoother operations. It will depend on how well you manage the MOQ. I hope after reading this article you have a clear understanding of customizing minimum order quantities. These limitations help wholesalers in better forecasting the demand for their products. You can also use software for better results.

Minimum Order Quantity FAQ

What is Minimum Order Quantity (MOQ)?

A Minimum Order Quantity is the minimum amount of product that a supplier is willing to sell in a single order. MOQ ensures the supplier can make a profit on the sale and justify the costs associated with producing or delivering the product.

How to Add a Minimum Order Quantity in Shopify?

You can use any third-party app from the Shopify store. These apps are well-built so it is easier to use. Or, you can do it manually through custom code. This method requires basic knowledge of HTML, CSS, and Liquid (Shopify’s templating language).

Why do Suppliers Set Minimum Order Quantities?

The supplier has to cover the cost of production and distribution. MOQ ensures that they still are left with a healthy profit margin. Suppliers set MOQ to obtain better pricing from their suppliers and maximize the efficiency of their supply chain processes.

Can Minimum Order Quantities Change Over Time?

They absolutely can! They can vary depending on the supplier, the product, and the market conditions.