Why do many famous businesses encounter losses sometimes? One of the biggest reasons is they messed up managing their inventory! Knowing how to manage wholesale inventory is crucial to success. You can take ASOS as an example. According to The Guardian, their profits dropped 68% year-over-year for the 2019 fiscal year. Why? They had an inventory system to update availability on the company’s website. But the system wasn’t pulling in any returning orders – for a WHOLE WEEK!

The more efficient you are, the more successful a wholesaler you become. Your efficiency will depend a lot on how you manage inventory. Don’t worry! We will help so that you don’t lose your brand’s reputation.

In this article, you’ll learn what inventory management is, its importance for your business, and some solutions that can make managing your inventory easier. We’re also going to talk about some common mistakes so you can avoid them easily. Look for some bonus tips!!

Table of Contents

Boost Your Sale With Effective Wholesale Inventory Management

The US Census Bureau estimates that as of July 2024, wholesalers throughout the country had combined sales of around 671.03 billion USD. What do you think? What’s the secret of this success?

Productive inventory management can be one of the determining factors for any B2B business. When it comes to wholesale, it’s all about carefully handling the bulk items purchased from manufacturers or distributors. Bulk purchasing can be tricky. They then sell these goods to other retailers. Sometimes, they market their products directly to consumers at a lower price than retail. Wholesale businesses manage large quantities of products. So, they should have enough supply to meet customer demand while minimizing overstock and storage costs.

Wholesale inventory management is the summation of acquiring, storing, and tracking B2B goods. This system covers everything from a business buying products from manufacturers to selling to another retailer or wholesaler.

There are many tasks involved in inventory management, such as:

- Submitting purchase orders (POs) for new inventory

- Calculating reorder points, economic order quantities (EOQs), and timing inventory replenishment

- Inventory control measures such as optimizing storage

- Logging inventory received from the manufacturer

- Tracking inventory levels

- Performing regular inventory audits

The Significance of Inventory Management in a B2B Wholesale Business

Effective inventory management reduces risks like overstock, shrinkage, or supply chain disruptions. Proper supervision can minimize carrying costs. It also ensures that you have the right products available to fulfill customer orders.

- Prevent stock out

- Optimize order management

- Avoiding over-ordering

- Ensuring higher customer satisfaction

- Saving time through automation and analytics

- Maximizing profits

Significance#1 Prevent Stock Out of Products

Isn’t it annoying when one demanding item is out of stock? It will take some time to restock it. You can lose valuable customers in the meantime. So, what’s the solution? Inventory management! You can predict when a product will run out of stock by keeping an eye on your inventory. It’ll give you an upper hand regarding these types of issues.

Significance#2 Optimize Order Management

Wholesale order management is controlling orders from start to finish. It includes entering orders, processing orders, and tracking shipments. Effective inventory management systems allow you to track stock levels accurately. So, it gets easier to maintain the whole order process.

Significance#3 Avoid Over-Ordering

It’s easy to order excess inventory when you don’t closely track stock. It can leave you cash-strapped in the short term. Over time, inventory overages also lead to bottom-line losses due to expired, outdated, and otherwise unsellable stock.

Significance#4 Ensure Higher Customer Satisfaction

You can fulfill orders accurately and on time with the right amount of supply. It will lead to repeat business and better customer relationships.

Significance#5 Save Time Through Automation And Analytics

An automated inventory management system, first of all, saves a ton of money and time. This type of system tracks a business’ stock levels across sales and storage facilities from receipt to fulfillment. It makes the process faster and more efficient.

Significance#6 Maximize Profit

Effective inventory management can help you avoid the costs of storing unsold goods. These costs include warehousing fees, insurance, taxes and all. It improves the overall cash flow. It will also minimize losses due to obsolescence and depreciation.

Problems You Might Face While Managing Your Inventory

As a B2B business owner, you might encounter many management risks. It can disrupt your operations and profitability. So, what can you do to avoid these issues? Learn about these problems so you know what to do.

Inaccurate demand forecasting is one of the serious hazards any B2B business may face. You might have to tackle cases like overstocking or understocking. It lowers cash flow or raises holding expenses.

Unreliable vendors and suppliers also pose threats. Delays or cybersecurity vulnerabilities can affect inventory availability and business operations.

Products with limited shelf life, especially perishable items, have to be sold in time. Otherwise, it might lead to revenue loss and logistical issues.

Inventory shrinkage is another significant crisis with losses amounting to billions annually. It can happen due to theft, damage, or mismanagement.

Inventory management costs can get higher from accumulating small expenses like overhead and storage. It can influence cash flow and customer pricing. Sales can be affected too.

Lastly, the bullwhip effect can lead to inventory shortages. Small changes in demand trigger significant supply chain disruptions.

These risks emphasize the need for effective management strategies. So, you can avoid operational and financial setbacks. Now, let’s look at how you can do it effectively.

How to Manage Wholesale Inventory in Just 7 Steps

Any wholesaling business that sells products must manage goods properly. If you don’t have goods to sell, or if you can’t find items to fill orders, you have no income. Simple! So, how to manage wholesale inventory for a B2B business? Here are some methods you can apply to manage your inventory.

- Define Product Sourcing and Storage Methods

- Decide How To Track Inventory Data

- Establish an Internal SKU Structure

- Arrange Spaces for Storage

- Demand Forecasting

- Set Up Inventory Receiving Procedures

- Keep Track of Inventory Levels

Step#1 Define Product Sourcing And Storage Methods

How you handle your inventory depends on where you get your wholesale products from and how you store them. Your inventory controls and procedures are managed internally if you keep all of your products stocked in your facility.

Nevertheless, you must integrate inventory procedures and data tools with their systems if you employ dropship providers or keep items externally in fulfillment centers or supplier warehouses.

Step#2 Decide How to Track Inventory Data

Inventory management requires careful monitoring of inventory data. Systems for managing inventories would be useful for this.

Step#3 Establish an Internal SKU Structure

Making a product within the company’s SKU systems is useful for monitoring and rapidly recognizing products while going about daily tasks. SKUs often consist of a string of letters and numbers structured to provide important information about an item quickly.

Step#4 Arrange Spaces For Storage

Organizing your belongings so that everything has a designated spot. It will help you complete inventory-related chores quickly and effectively. Assign each product to a designated place after organizing and identifying storage spaces, such as racks, shelves, and bins, if you manage inventory in your business or store.

Step#5 Demand Forecasting

You did expect this point, didn’t you? I mean how can we talk about wholesale inventory management without demand forecasting? It is the act of accurately predicting future demand for your products. If you do it well, you ensure that you’ll have the right amount of inventory on hand. It will be easier for you to meet the customer demand.

Step#6 Set up Inventory Receiving Procedures

Promptly receiving inventory shipments is another crucial feature. Inventory that has not been checked in and is not appropriately shelved or exhibited cannot be sold or sent. Thus, prioritizing inventory receipts in your plan for managing your inventory makes sense.

Strategies like “last in, first out” (LIFO) or “first in, first out” (FIFO) can help too. Using the FIFO approach, which puts new items behind older stock so you sell older goods first, is often a wise move. When it comes to perishable foods and products with expiration dates, like cosmetics, this is particularly crucial.

Step#7 Keep Track of Inventory Levels

Most inventory-driven businesses do an annual inventory count, called an audit, for tax purposes. This compares a physical count of all goods in stock to the inventory quantity on hand (QOH) shown in the data records. However, discrepancies found in annual counts are nearly impossible to trace and account for since it may be months after the errors occurred.

Interim counts such as cycle counts and spot checks help you find and remedy small inventory inaccuracies before they become big problems.

6 Mistakes to Avoid While Managing Inventory of a B2B Business

Some inventory mistakes can cost you hundreds of bucks. Read these and try to avoid the mistakes.

- Manual Spreadsheet Tracking

- Excess Stock

- Ordering Too Little Stock

- Lack of Automation

- Lack of Adequate Staff Training

- Leaving Your Inventory Checks So Long

Mistake#1 Manual Spreadsheet Tracking

Keeping an Excel sheet or physical documents was the most popular inventory system, back in the old days. If you have a small business, this process might still work. But it will cost you your valuable time. The chances of errors will be much higher. As your store grows, manually managing it will be harder.

Mistake#2 Excess Stock

Surplus or excess inventory ties up capital and stops you from reinvesting. It also takes up shelf space. So what to do if you have more products than you need? You can offer overstock products as freebies and incentives or sell them at a discounted price. Best practices for bulk order discounts might help you clear excess inventory. Arranging a limited-time offer or Shopify flash sale can create buzz among your customers. You can also donate these products. Donating is a good act of service to help those in need. This charitable giving strategy will also demonstrate your brand’s commitment to a good cause.

Mistake#3 Ordering Too Little Stock

Ordering not enough products is also a product like excess stock. You won’t be able to fulfill orders. It will damage customer retention, trust, as well as revenue.

Mistake#4 Lack of Automation

Just like we discussed before, manual tracking will consume a lot of your time. It will cause fundamental losses because of errors, stock-outs, overstocks, etc. Automation can transform your business and help remove common inventory mistakes.

Mistake#5 Lack of Adequate Staff Training

To name just a few, this can lead to disparities in stock descriptions, stock levels, accounts, and the accurate status of your orders. The new inventory management system isn’t easy to pick up straight away. Always ensure your staff knows your automated inventory systems.

Mistake#6 Leaving Your Inventory Checks so Long

You’ll need more time to fix errors the longer they remain unattended. Conducting bi-monthly inventory counts can be a wise option. So you don’t have to spend days locating hundreds of lost items over a year.

Benefits of Using a Wholesale Inventory Management Solution

So many of your inventory management problems can be fixed with great tech. Good inventory software can save you some major headaches. It guarantees that crucial assignments and information are noticed.

Several tools are available to help reduce the workload associated with manual inventory management. You can have a smaller budget for more complex automation software.

Your inventory will be under your better control. It’ll give you a unified overview of your business. An inventory management system helps you monitor the demand and current stock levels. So, you have a clear idea of when to restock products. The reports inform you of the demands. So you don’t waste money on products with low demand.

6 Tips For Finding The Best Inventory Management Software For a B2B Business

There are hundreds of wholesale inventory management solutions out on the market. Finding something that meets your needs well might be complicated. These six suggestions will assist you in selecting the best inventory software for your particular business requirements.

- Understand your need

- Set a clear budget

- Surf through different software and compare features

- Try to talk to the users of the software

- Try The Demo

- Evaluate the product fit and ask questions

Tips#1 Understand Your Need

There are a lot of inventory management software available. Some of them offer a full management solution. Some apps focus on specific features to help with specific problems. So, you need to figure out what might help you.

Tip#2 Set a Clear Budget

A budget will filter out products that don’t suit your budget. It ultimately generates a shorter list of products you would need to consider. It will also help you to understand the cost benefits of purchasing inventory software.

Tips#3 Surf Through Different Software And Compare Features

Many websites offer comparison features. You can go and compare a few software products. Then you’ll understand how they differentiate themselves from the competition. You can filter out the products that don’t have the features you need.

Tips#4 Try to Talk to The Users of The Software

They can give you insights about the pros and cons of the software. You’ll get a great sense of how the product appears to be used.

Tips#5 Try The Demo

We told you to understand your needs in the first point. But how are you going to know if the features are good or not? Most management products come with a demo or trial period. So, sign up for the free trial or request a demo after you’ve got a shortlist.

Tips#6 Evaluate The Product Fit And Ask Questions

During the demo or trial period, keep an eye out for how well the products fit your needs. It’s also important to look at how easy or difficult it is to use it. Look for any documentation. A well-designed and organized product must have straightforward documentation available.

Wholesale Inventory Management With Third-Party Bulk Order Apps

You don’t always have to install fully integrated software. Some third-party apps offer amazing features that will help you maintain your wholesale inventory. If you have a Shopify store, then this section is just for you. Shopify offers many management apps. Take this one as an example.

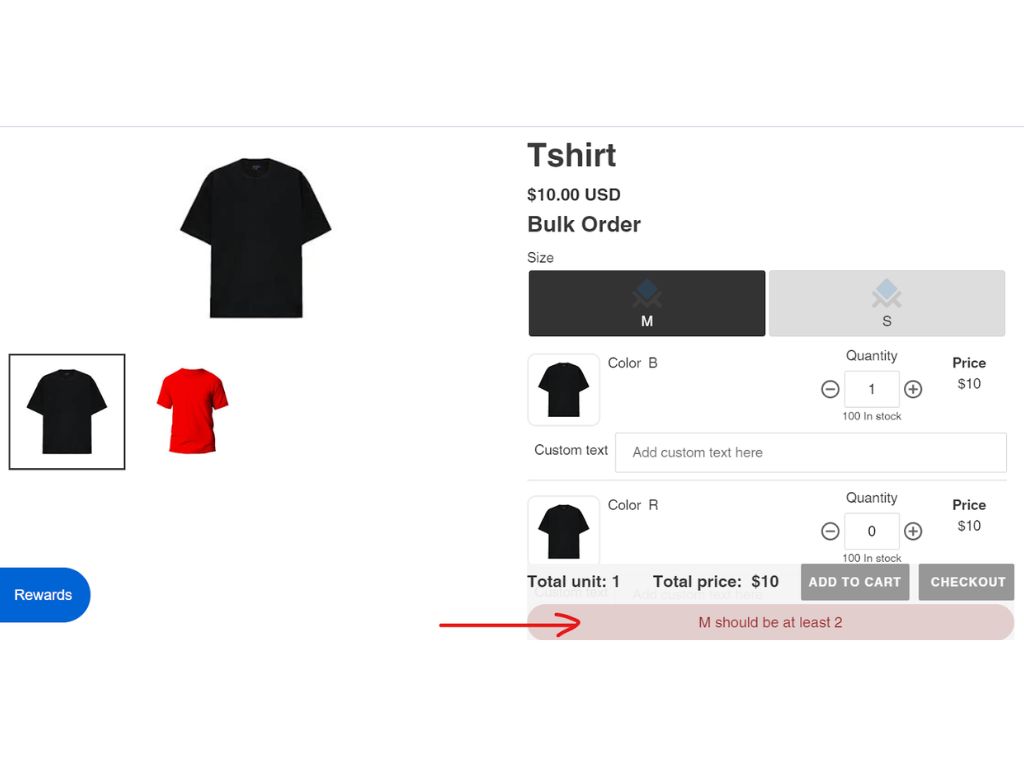

This bulk order app offers quantity restrictions, variant restrictions, and limits based on order value. Here you can see that a minimum order quantity restriction is added to the size option. The customer has to select at least two M-size or two S-size t-shirts, no matter what the color is.

A one-click bulk order app on Shopify like this implements MOQ strategies. The right MOQ keeps your inventory in check. You can confirm the right MOQ with the right demand forecasting. It is important because otherwise you’ll oversell or undersell your products.

Conclusion

You buy some products and sell those at a higher price to the customers. Sounds very simple! But is it actually that simple? Maybe it isn’t. But with proper wholesale inventory management, things can get easier. We will be delighted if our writing even remotely assists you.

Wholesale Inventory FAQs

What is Wholesale Inventory?

Wholesale inventory consists of finished goods products received from manufacturers or distributors that have not yet been sold to customers. Wholesalers tend to work with retailers, selling them bulk quantity items at discounted prices that allow the retailers to make a profit via markup.

What Are The Main Steps in Inventory Management?

Assess what you have now and review what you have. Analyze sales and identify items to repurchase or retire.

How do You Manage Bulk Inventory?

First of all, define product sourcing and storage methods. It will make handling inventory easier. Then decide how you will track your inventory data. Establishing an internal SKU structure would be a great idea. Assign each product to a designated place after organizing and identifying storage spaces, such as racks, shelves, and bins. Predict the future demand as accurately as possible, so that you can have the right amount of inventory on hand. Set up inventory receiving procedures. Last but not least, keep track of inventory levels.

How to do an Inventory List?

You can get an organized summary of every product a business has in stock from its inventory list. It usually has information about each item’s SKU number, name, description, unit cost, quantity, and reorder point.